Certifications for all Structural Steel Buildings

We are seeing more and more the variation in building and structural design through the ever evolving flair and technical ability of today’s architects.

Small and simple functional buildings, such as a warehouse for example, may be constructed using standard I or H shaped column and beam girders. On the other hand, larger, more distinctive, or iconic buildings such as airports or stadia, may have a more complex mix of structural steel used for the substructure to achieve the desired appearance or functionality. Most of the structural frames that we see these days are now built utilising what could be described as ‘non-standard’ steel components. Drivers for this could be budget optimisation as well as aesthetic or functional drivers.

The subsquent need for more robust and consistent method to determine the fire protection requirements has evolved and has been done through testing, analysis and assessment to a common standard. Test and assessment standards were developed for standard construction methods that are not covered by:

- BS476 Pt 20 & 21 - Fire Tests on Building Materials and Structures

- EN 13381-8 - Applied Reactive Protection to Steel Members

These construction methods include:

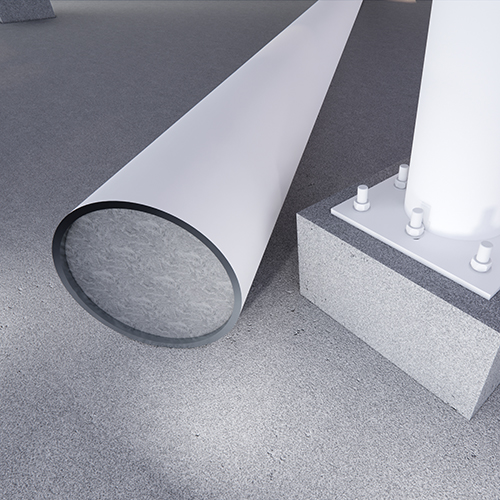

- Concrete filled hollow tubes.

- Steel beams with web openings – also known as cellular beams, cell beams or long span beams.

- Solid steel rods, circular or rectangular, such as used as tension rods for facades.

Each type of structural element now has its own specific standard to assess the fire resistance performance of the protection installed. These new standards were added to the EN13381 series detailing test methods for determining the contribution to the fire resistance of structural members. No new additions were made to BS476 as the standard has been superseded, although it remains valid for testing. EN13381 is acceptable in the UK market, as well as BS476.

In practice, this means that for standard structural steel, either BS476 Pt 20 & 21 or EN 13381-8 is acceptable and the preferred or most competitive used.

But, for ‘non-standard’ structural steel, concrete filled hollow tubes and solid steel bars or rods, only the EN 13381 standard is acceptable.

Therefore, given that there is a specific published standard, it is no longer acceptable to use any other method than those described in these standards. Practices that have been used historically are no longer acceptable if they differ from those described.

The additional standards relating to ‘non-standard’ structural steel covered in the EN13381 series are:

- Tension rods or solid steel rods

|

Structural support for facades walls, i.e., airports.

Issue: Steel mass provides heat sink, meaning paint reacts differently to normal hollow tubes.

Solution: EN 13381-10 (not accepted in Germany).

- Cell, cellular or long span beams

|

Lighter weight, longer span, maximising floorspace, i.e., retail and car parks.

Issue: Paint retracts from edges in a fire. Different for every paint. Every shape is different – circles, square and distancing.

Solution: EN 13381-9.

- Concrete filled hollow tubes

|

Cost effective strength solution or FR solution after design.

Issue: Concrete mass provides heat sink, meaning paint reacts differently to normal hollow tubes.

Solution: EN 13381-6.

This adds a significant additional investment in order to ensure that the products offered are appropriate for all of the construction methods encountered on a typical construction project. At Nullifire are committed to ensuring that all of our products are tested and assessed to the latest and most suitable standards needed for the market.

Find your Nullifire solution for the different steel geometries:

The Nullifire intumescent coating range offers three technologies - water, solvent and hybrid based. With these comprehensive range Nullifire you have the right coating for your individual project and requirements to be total compliance!

| Approval | SC604 / SC605 | SC803 | SC901 / SC902 |

| Technology | Solvent | Water | Hybrid |

| Optimised performance | 60 min | 60 min | 120 min |

| 3rd party certification | Warringtonfire, NL | Warringtonfire, NL | Warringtonfire, NL |

| Concrete filled hollows | ✔ | ✔ | ✔ |

| I sections | ✔ | ✔ | ✔ |

| Hollows | ✔ | ✔ | ✔ |

| Hollows beams | ✔ | ✔ | ✗ |

| Cell beams | ✔ | ✔ | ✔ |

| Tension rods | ✔ | ✔ | ✔ |

Approved certifications

For the different steel components, the Nullifire coatings have the approved certifications in place.

- BS476 Pt 21-21

- EN13381-6 - Applied protection to concrete filled hollow steel columns

- EN13381-8 – Applied reactive protection to steel members

- EN13381-9 - Applied fire protection systems to steel beams with web openings

- EN13381-10 – Applied protection to solid steel bar in tension (not accepted in Germany)

Get in touch with one of our team members today to enquiry about your project and particular needs.

Related Articles

.jpg)