Fire Barriers: The Key Element of Effective Fire Compartmentation

There are many factors to consider when it comes to ensuring an appropriate level of fire safety in a building. Along with existing Passive Fire Protection (PFP) methods, special attention should be paid to fire compartments.

Compartmentation is dividing the space into smaller sections constructed to constrain the fire in one space to limit the spread of flames, smoke and toxic gases within it.

However, if not all penetrative services are properly sealed with the right and proven fire protection materials, then even fire-resistant walls, floors, and ceiling can’t effectively prevent the spread of fire, smoke and hot toxic gases. All of this makes the building potentially unsafe for the occupants.

How do you achieve the proper level of fire compartmentation?

Using Nullifire FB750 Intubatt is the right answer, as the product enhances fire performance in compartments breached by penetrating services. It supplies a fire, smoke, thermal, acoustic and air pressure seal.

FB750 is a lightweight, easy-to-cut fire barrier that features elastomeric, ablative, water-based sealant with a 30-minute fire rating. It is covered with Optifire, a unique traceability identifier, activated by UV (Ultraviolet) light. Besides this, it is also proven to span large areas and it is an excellent acoustic reinstatement product with an air pressure seal.

This is a primary seal that requires added Nullifire products to function properly, namely FS702 Intumastic Fire Resistant Acrylic Seal and/or FS712 Intumastic Fire Resistant Acrylic Coating. As a primary seal, it may be used directly around the following service types in both walls and floors:

• Cable trays.

• Individual cables to 5 - 80mm sheathed or non-sheathed.

• Grouped or bundled cables.

• Non-combustible pipes.

• Non-combustible insulated pipes.

• Ducts and dampers.

•

• Non-combustible conduits with or without cable load.

• Timber elements.

FB750 is suited to many combustible elements when used with secondary products such as Nullifire FS709, FP302, FP170, FP220, FP333:

• PVC, PEX, PP, PPR, MLCP, PB pipes.

• PE pipes (HDPE MDPE LDPE).

• Combustible conduits with or without cable load.

If you are wondering, where exactly FB750 can be used as a penetration seal, these are installation examples of how the components can be sealed:

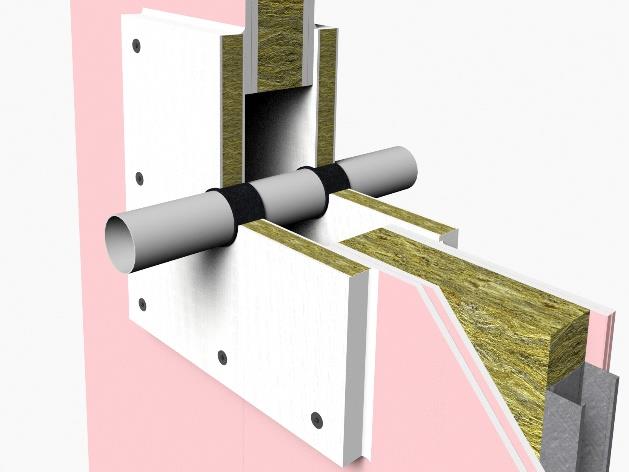

Flexible walls

These walls have a minimum thickness of 75 mm and consist of steel or wooden studs covered on both sides with at least one layer of 12.5 mm thick boards. These walls should be classified according to EN13501 pt 2 to allow the transfer of data to other types of walls.

Apertures created through such wall types shall be constructed as per the requirements shown in tables contained within ETA 121/0412.

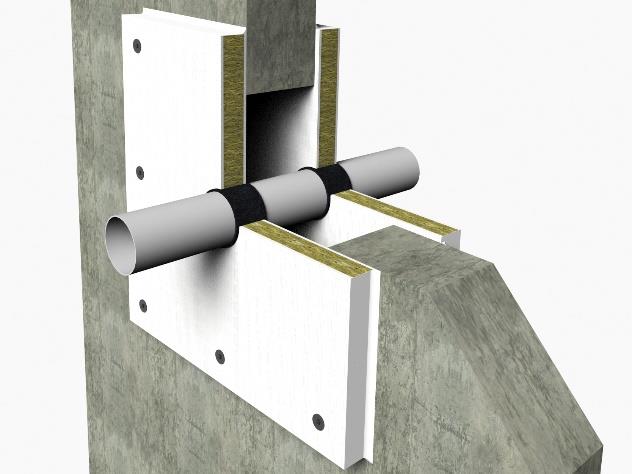

Rigid Walls

The wall must have a minimum thickness of 75 mm of concrete, aerated concrete, or masonry, with a minimum density of 650 kg/m3.

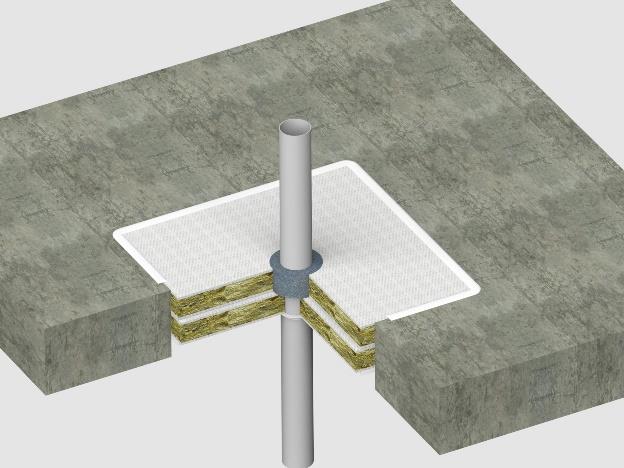

Rigid Floor

The floor must have a minimum thickness of 150 mm and be made of aerated concrete or concrete with a minimum density of 650 kg/m3. For the required fire resistance period, the supporting structure must comply with standard EN 13501-2.

FB750 is recommended only for small openings on a floor. Although it can be used in larger openings and has proven effective there, we do not recommend it because FB750 is not a load bearing product. If foot traffic is foreseen, we usually recommend Nullifire FR230 as the primary sealant.

To deliver effective fire protection, it might be necessary to consider more complex issues, that require a more particular solution. In this case, you will require professional support to complete compartment reinstatement once all services are installed, and access is restricted.

Testing FB750 Intubatt

FB750 Intubatt has been extensively tested for various usage properties and combines perfectly with many other Nullifire Fire Protection products. Proven by EN tests (1366-3), valuable Compartmentation Zones restore their maximum efficiency and make the building safe again. This fire-resistant barrier has also been tested for standard, special, and custom applications and is suitable for use on many different substrates.

FB750 Intubatt is by far the most tested product within the Nullifire fire protection range and is always tested and assessed to the latest and correct standards for the UK and European markets.

Every test we carry out involves the installation of FB750 Intubatt ducting prior to installation. Our approach is based on the needs of the building, meaning the fire test is carried out as you would like on-site. This may not be the fastest method of test design, but it is how we ensure that the requirements are met and that the reality and considerations/difficulties of on-site application are accurately represented.

FB750 fire safety testing in numbers:

• 41 test reports completed.

• 84 hours of fire testing.

• 2000+ meters of cable used in a single test!

Download our FB750 Application Guidance for free!

Our complete FB750 Application Guidance is available to download from our website. Used in combination with the ETA 21/0412, it will guide you through the Fire Stopping process and make sure that FB750 is installed correctly.

Have any questions? Feel free to contact us!