Fire resistance identifiers: "Up to" or "Optimised to"?

You may have noticed that several of our products have the products Fire Resistance performance expressed in different ways. This is predominantly expressed as:

- Up to X minutes, or

- Optimised to X minutes

Where X is the Fire Resistance such as 30, 60, 90, 120, etc., etc..

Why is Fire Resistance expressed differently for Nullifire products?

It is simply down to the testing that is needed to generate the approvals used to market the products.

Some tests are absolute. The test or approval criteria are black and white where a test sample has to achieve the set criteria.

An example would be a pipe seal is tested for fire resistance and maintains performance for 125 minutes. It can be marketed on the approval for ‘Up to 120 minutes’ (as markets are typically split into 30 minute segments). The performance is not enough to use for beyond 120 minutes, such as ‘Up to 150 minutes’.

Other tests are not absolute and the approval depends on a series of test results to be analysed together to produce an assessment.

An example is intumescents for structural steel.

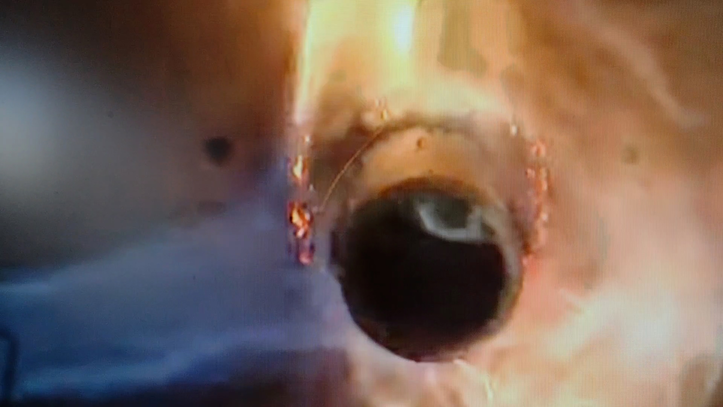

![[Translate to English (GB):] Fire testing Intumescent coating Nullifire](https://nullifire.azureedge.net/Sites/CelumExport/03_-_Public/Nullifire/International/fires_testing_before_WebImageL.png?rmode=max&width=372&height=279)

Because of the multitude of steel sizes and geometries that exist, performance needs to be determined over a range that the product intends to be marketed for. The standards dictate that this is done in a matrix format with minimum and maximum of Dry Film Thickness (DFT) and steel sizes (Hp/A) tested, and several points in between.

For structural steel, this may include beams, columns, circular tubes and square/rectangular tubes over a range of paint thicknesses from the minimum, up to an elected maximum. This means that one product may have many test samples produced – from 100-250 individual test pieces.

If the intention is to offer a product that protects every structural steel size/geometry that would be encountered on a 60 minute building project, this means that inevitably some will achieve beyond that. Heavy steel at high DFT may achieve protection times of 90 minutes or beyond.

Therefore, when all of the results are analysed to produce the loading tables needed to market intumescents, they always contain additional fire resistance loadings than the targeted fire resistance, i.e:

- A 60 minute product almost always has some limited 90 minute capability.

- A 90 minute product almost always has some limited 120 minute capability.

- A 120 minute product almost always has some limited capability beyond 120 minutes.

A new way of communication by Nullifire

Therefore, for the Nullifire intumescent range, we are introducing the ‘optimised to X minutes’ identifier. This will be used to identify the fire resistance period that we would reasonably expect to be able to meet every requirement.

This is to move away from stating the maximum fire resistance period where maybe a limited amount only can be protected that would be sufficient for only a fraction of projects (where another product would be best suited).