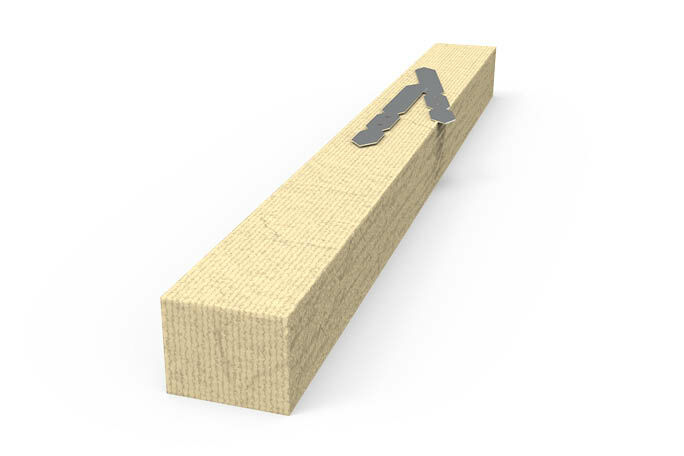

FJ260 Cavity Barrier

FJ260 Cavity Barrier is a close state cavity barrier made of rock mineral wool and designed to maintain the required fire resistance when following fire compartment lines.

Usage/purpose

FJ260 Cavity Barrier is used as a cavity barrier, within external wall cavities in all required locations plus at the junction of compartment floors, compartment/party walls and around openings. It maintains

fire resistance performance of cavities of up to 600 mm and only requires 5 mm of compression when fitting.

- Up to 2 hours fire resistance

tested to EN 1366-4 (up to EI

120) - Reaction to Fire class A1

(unfaced) - Suitable for cavities up to 600

mm - Easy to install

- Tested including SFS Systems

with calcium silicate or cement

particle boards - Suitable for use vertically and

horizontally - No maintenance required after

installation